CU+Stainless Steel: Antimicrobial Properties + Premium Raw Material

Due to its germ-proof properties, copper has been widely used throughout history.

Today, we must be more proactive against new generations of microbes that are constantly renewing themselves and becoming more powerful. We must create clean, hygienic environments that prevent the spread of microbes.

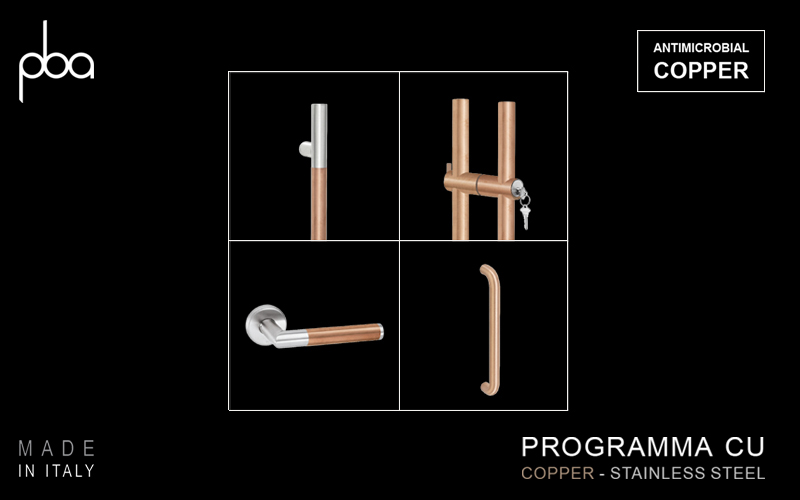

PBA®, the new series of PBA CU+ stainless steel, proves to be an important solution for reducing contamination and creating healthy and clean environments. The new PBA series features elegant and contemporary designs made of CU+ stainless steel, manufactured with the finest raw materials.

Designers can choose handles, door handles, locking and non-locking handles, and glass door locks in the CU+ stainless steel series, made of pure copper (99.9%) or pure copper and stainless steel, for use in glass doors, monolithic doors, and windows.

In designing this series, PBA used the finest quality stainless steel, 316L, and the finest The antimicrobial material is aimed at producing the highest quality using pure copper. This definition of high quality encompasses both mechanical durability and EPA-registered antimicrobial defense properties, which only copper offers against pathogens such as MRSA, S. aureus (previously STAPH), and E. coli.

COPPER HAS NATURAL ANTIMICROBIAL PROPERTIES AND IS THE FIRST STURDY SURFACE MATERIAL TO RECEIVE EPA REGISTRATION IN THIS FIELD. THIS REGISTRATION IS SUPPORTED BY EXTENSIVE ANTIMICROBIAL EFICIENCY TESTS.

A RECENT ARTICLE IN THE NEW ENGLAND MEDICAL NEWSPAPER MENTIONED COPPER'S MUCH LESS VIRUS-HARMONIZING PROPERTY THAN OTHER MATERIALS.

CU+STAINLESS STEEL PRODUCTS CONTRIBUTE TO PLANNING CLEANER, MORE HYGIENIC ENVIRONMENTS, BECOMING A PART OF THE DESIGN OF HIGH-TOUCH SURFACES, ESPECIALLY IN HIGH-TRAFFIC SPACES, SUCH AS OFFICES, MEETING ROOMS, HOTELS, AND HOSPITALS.