Mirror Efect Metal Laminates

Mirror Laminates:

Our glossy metal mirror-effect laminates are lighter than float glass mirrors. You get a true-to-life mirror reflection. Mirror laminates are easily bonded to materials such as MDF and particleboard. They are lightweight, do not stretch, expand, fade, or deteriorate due to moisture.

Areas of Use:

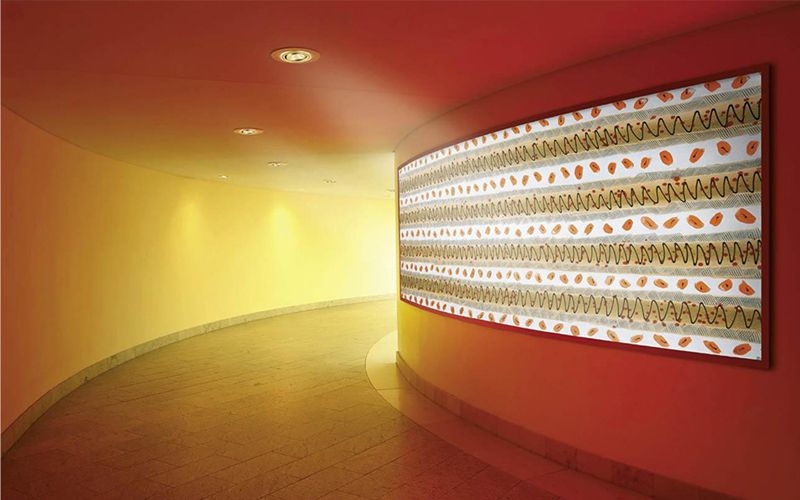

Suspended ceilings, counters, wall and column cladding, office furniture, hotel rooms, reception desks, entrances, foyers, kitchen furniture, home furniture, store furniture, etc.

Technical Specifications:

Dimensions:

2440*1220mm.

3050*1220mm.

Thickness: 0.9mm.

Things to consider when working with metal laminates

We recommend using metal laminates for balancing when processing metal laminates.

Since metal primers are expensive for balancing, our company offers our brown primer in 0.8-0.9 mm thicknesses as an economical alternative. A trial run should be conducted for the brown primer, and once it's deemed successful, production should begin.

When processing metal laminates, the maximum temperature should not exceed 50 degrees Celsius in conventional presses. Pressing should be done at lower temperatures. The recommended adhesive types are PVA and contact adhesives. Glues that have accumulated dust and particles should not be used outdoors, or they should be used after removing foreign matter through a strainer. Otherwise, particles that settle under the laminate with the glue will cause boils on the laminate surface.

You can address any defects in the press plates by applying a protective plate.

The applied pressure should be low. It should not exceed 1.5-2 kg/cm².